Half Round Copper Gutters w/Double Scroll Cast Brass Hangers

A copper rain gutter system can improve the appearance of your home like no other gutter system.

Copper gutters are found on architect-designed custom homes, historic homes and other high-end homes. Today, the Earth houses some 690 million tons of copper now being mined, with another 3,500 million tons as yet to be tapped. [2] There’s no shortage of copper available, yet the economic forces that affect mining cause the price of copper to fluctuate, sometimes dramatically. Some major mining companies even forecast shortages from time to time, but those are strictly economic shortages—not true shortages—for our planet is a virtual treasure box of copper. [3]

The Attractions of Copper Gutters

Copper is a highly lustrous metal that can be polished to a brilliant sheen. It is durable, strong, and corrosion-resistant. It is both ductile (can be stretched or drawn) and malleable (capable of being rolled into sheets and bent into other shapes without tearing or fracturing). It’s easy to work with and makes the ideal metal for rain gutters.

Concord Sheet Metal’s copper gutters add real beauty to a home and last for many decades with virtually no maintenance. In addition to its corrosion-resistance, copper prevents the growth of algae, mosses and lichen. When these nuisance plants begin growing in a non-copper gutter system, they block the clear flow of rain water, adding to your maintenance headaches. [5]

Copper reacts with the atmosphere to form a patina, which adds a distinguished, elegant and sophisticated appearance to your entire home. Patina can range from blue, green, brown, or even black, depending on the surrounding environment. If you like, you may choose to have Concord Sheet Metal pre-patina your gutter and accessories to immediately give the richness of a patina to your gutter system. Most of the gutters pictured on our website have been pre-patinaed by Concord Sheet Metal.

Rain gutters are like the frame on a picture. A properly sized and stylish copper gutter complements and enhances the home’s appeal, while the wrong style or improperly sized gutter detracts from that appearance. All considered, copper gutters add character, distinction and class to any home or structure.

Gutters Prevent Structural Damage

Flashings carry water off the roof. Gutters and downspouts direct water away from your home. In most parts of the U.S. where seasonal rainfall is significant, water running from your roof to the ground can eventually cause damage to the foundation of the structure. Those torrents of water repeatedly falling from the roof can also lead to basement flooding, mold, erosion, damage to wood and paint as well as decks, patios and landscaping. Unless you live in the driest areas of Arizona, New Mexico, Utah or Wyoming—the four states with the least annual precipitation—rain gutters are probably needed to prevent these types of damage. [6]

Copper Costs More

While copper gutters are beautiful and never need painting, they do cost more—but only initially. Homeowners find their lifetime cost of ownership puts copper about the same as aluminum gutters, but with far less maintenance and care.

According to the International Association of Certified Home Inspectors, [4] copper gutters have an expected lifespan conservatively rated at well beyond 50 years. It is not uncommon for copper gutters to last as long as 80 to 100 years, while aluminum, galvanized steel and vinyl gutters often need replacement every 20 years or so. Each replacement requires new material, tear-down of the old gutters, scaffolding, painting, disposal fees and more. As such, the lifetime cost for copper competes nicely with ordinary gutters. Furthermore, some 90 percent of the copper used in making gutters comes from recycled material, while vinyl, aluminum and galvanized gutters often end their lives discarded in landfills. Copper is a much “greener” solution that does not have the same negative environmental impact as non-copper gutters.

Many homeowners view copper gutters as an investment that increases the curb appear of a home just as dramatically as it raises the resale value of the property. In the final analysis, you’ll want to compare the initially higher cost of copper with your objectives for low maintenance, longevity, durability and stylish appearance.

Copper gutters are soldered together which requires less installation labor than ordinary galvanized gutters that require riveting and sealing. Further, soldered joints don’t leak at the seams that join each segment. Other types, such as aluminum and galvanized, are joined together with a caulking sealer that requires periodic maintenance to prevent leaks. In all, the initial installation cost for copper gutters can run 1.5 to three times that of aluminum, galvanized or vinyl gutters.

Choosing Among Copper Gutter Designs

The purpose of a gutter system is to capture the water as it flows off your roof and carry it to the ground, preventing damage to the foundation of the building and preventing water damage to the structure. Choosing a specific type of gutter design depends on two key factors: If you live in an area where rainfall is heavy, you will need gutters with a size and shape capable of carrying water from your roof without overflowing. The total square footage of your roof determines the gutter capacity required. Also, the steeper your roof pitch, the higher capacity gutter you will need. Rain water will careen much faster off a steep roof than one with a milder pitch, and your gutter needs the capacity to handle that rush of water.

Half Round Copper Gutters

Half Round Copper Gutter w/Star Outlet & Cast Brass Hanger

These gutters are often used on custom homes and homes that emulate historical styles of construction where visual appeal or historical accuracy are essential. Architectural style is also an important consideration when choosing your gutters. Half round copper gutters come in sizes ranging from four inches to more than seven inches across, capable of diverting small or large amounts of water away from the structure.

K-Style Copper Gutters

Custom 8″ Ogee Copper Gutter

Also known as Ogee gutter, this is the most popular gutter design in the U.S. The majority of homes use K-style gutters. Their flat, vertical side allows attaching directly to the fascia boards, making installation somewhat faster and more economical than half-round gutters. These copper gutters with the characteristic “S-shape” front wall are made in both standard 5″ and 6″ widths. For custom jobs, larger and smaller sizes are available in up to 20′ lengths.

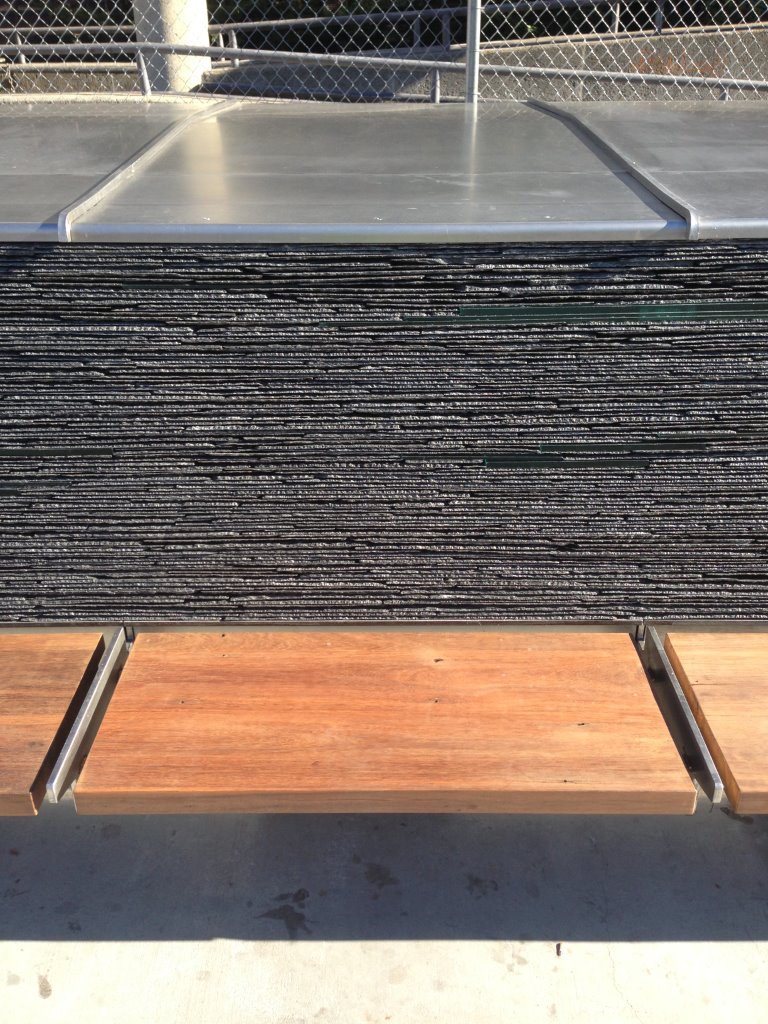

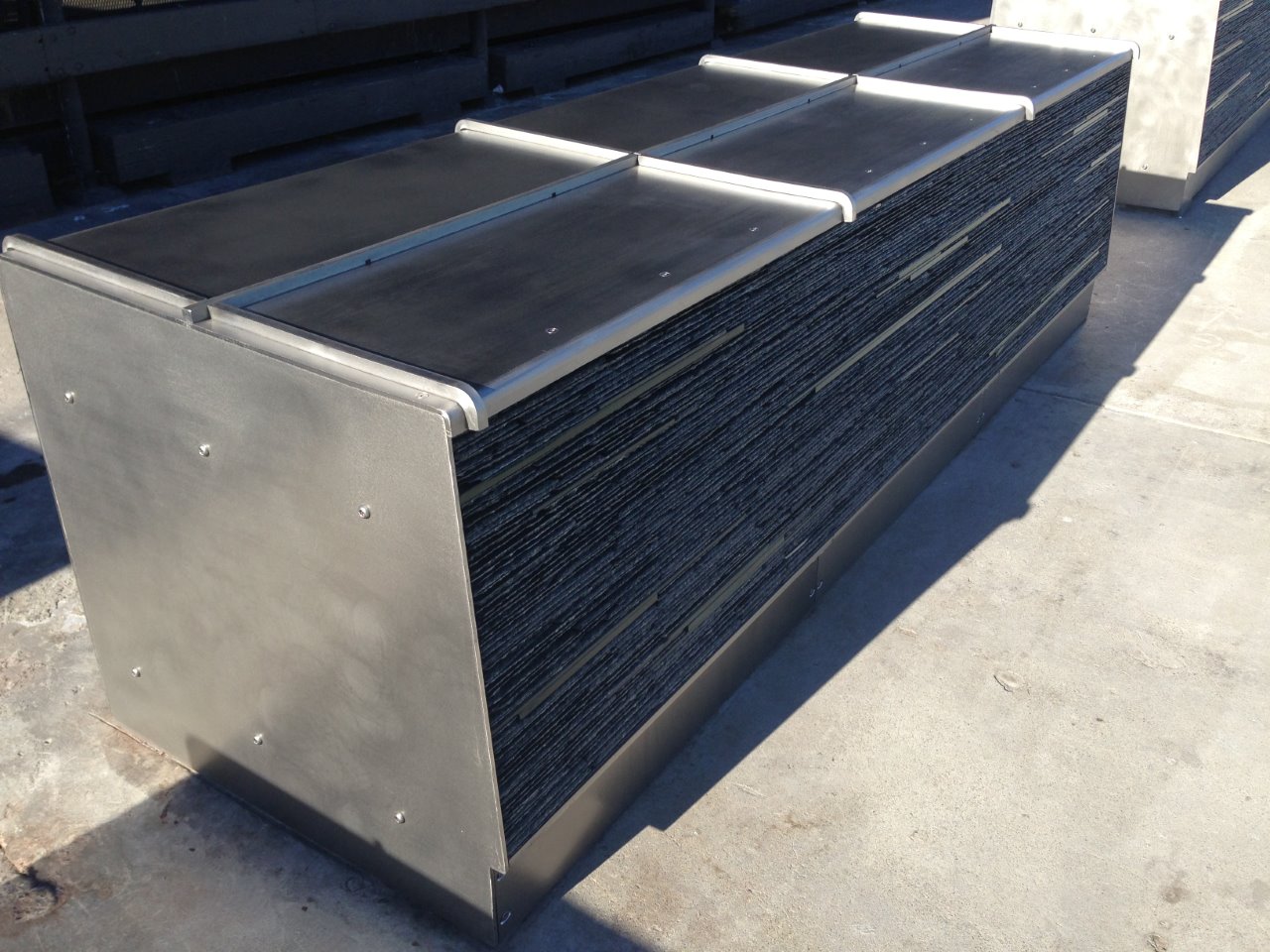

Eclipse Millennium Copper Gutters

Eclipse Millennium Copper Gutter with Green over Brown patina

This unique, patented gutter system adds the rich look of crown molding to your entire home. Should the gutter ever become clogged, water would flow over the front of the gutter—not back up the roof. Ideally suited for tile roof systems, this design handles high velocity water flows and requires virtually no maintenance. [7]

Typical Installation Details

The best way to obtain a detailed quotation for copper gutters is to contact us here; by phone at 800-799-1900; or, by fax at 925-680-6569. In the meantime, here are some general guidelines you can use to roughly estimate your installation costs.

Copper is measured in ounces per square foot. Copper gutters are generally made of 16 oz or 20 oz material. You can find current pricing for various gutter designs and weights at our online store.

As a general guideline, installation costs run about $1,000 to $1,200 per day for labor, plus materials. An installation crew with two workers can install about 130 linear feet per day, however if many mitered corners are involved, that may drop to around 75 linear feet daily. Other factors such as roof pitch, whether fascia boards are perpendicular to the ground rather than slanted, and overall accessibility will affect the number of linear feet workmen can install in a day.

Concord Sheet Metal is a fabricator only, but we may be able to provide you with contact info for an experienced installer in your area.

Sources: