Antimicrobial Copper is Not a Coating

“Copper alloys are actual engineering materials. We are talking about solid metal doorknobs, bed railings and push plates. There is a catalog of actual hospital fixtures and components that are readily available for purchase today,” said Michels. “The power of antimicrobial copper is that it continues to work. One of the tests we had to do for the EPA was to inoculate a surface eight times in a 24 hour period with a load of bacteria, and it kept reducing the bacteria – without even cleaning it in-between. It actually kept on working even though the inoculum of live bacteria was placed on top of the dead bacteria. ”

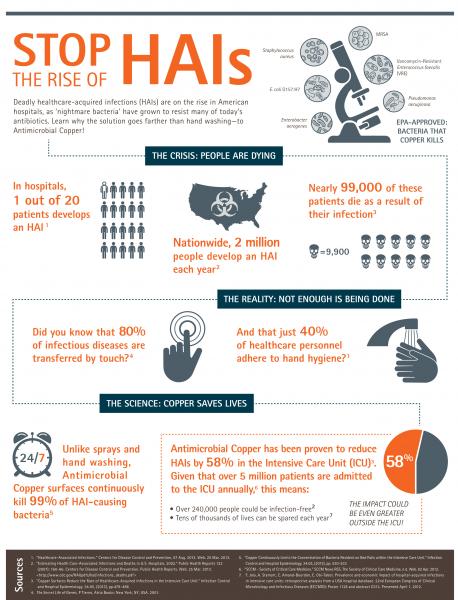

He goes on to state some frightening facts: “Right now, if you go into a hospital without an infection –for tests or a minor surgical procedure, you have a 5% chance of coming down with an HAI. If you get an HAI, you have a 5% chance of dying from it. If you become an Intensive Care Unit patient, the percentage increases to 25%. Two million people get infections in U.S. hospitals each year; 100,000 die.”

“That is the equivalent of a fully loaded jumbo jet crashing every day, all year long, with no survivors ─ not very good odds.”

Copper took the back seat when antibiotics came into being, but soon after the use of antibiotics, super bugs began to develop that required newer and stronger antibiotics – or were resistant to all antibiotics. Because of the way copper works, Michels explains that simply isn’t likely to happen. “We have yet to meet a super bug that copper can’t kill. It’s all in the way it works. It compromises cell wall integrity and all vital functions of the bug stop. Period. That’s how it kills them.”

Comments on this entry are closed.

The findings are astounding!

Would never have equated Hospital infections on the materials in place. Scary!

Great article.